Published by admin on 01 Dec 2009 at 03:21 pm

The Making Of A Cedar Shaft Modern Product From Oregon’s Coast By Sam Fadala

The Making Of A Cedar Shaft

The History, Construction And Uses Of This Ancient But

Modern Product From Oregon’s Coast

By Sam Fadala

The handmate arrow for the compound bow has been the aluminum shaft, and with good reason. Aluminum is a fine arrow material, and the company responsible for turning out the bulk of these arrow shafts has been responsible, honest, and innovative. While the aluminum arrow maintains the kingpin, there are, however, some alternative types that have been seeing more play lately. Most of these are space-age inventions, such as the graphite, or improvements on old designs, such as the stainless steel arrow. Another, however, is an ancient arrow material – cedar. These wooden arrows were around from the start in America, as the Northwestern Indians, Coquille and others found cedar to be superb as a shaft material. It was then. It still is today, and for many reasons.

Contrary to popular notion, it still is a highly useful arrow material, not only in the longbow, for which it is aptly applied, but also in the compound. The tree that yields these arrow shafts is found only along the coastal areas of Oregon, near Port Orford country, and the arrow has long been known as the Port Orford cedar type. Speculation holds that the first cedar trees to grow in this area were begun as seedlings thousands of years ago, carried to Oregon on the Japanese current. Japan is the only place that has an abundance of these trees and that country uses the wood for building as well as countless other applications. America uses its cedar primarily for arrow shafts and by-products of the arrow industry because the wood is so well suited for this, while not being particularly excellent for construction.

One of the main attributes of the cedar arrow is cost. Shafts can be purchased in quantity and fine, straight arrows are then handmade by the archer at a fraction of the cost that finished products bring commercially. This pastime is great fun, as well as money-saving. As long as there are tree squirrels and rabbits to be hunted, where arrow loss and breakage is high, the inexpensive cedar is going to stay around. On varmints, especially those which inhabit rocky terrain, such as rockchucks and ground squirrels, the cedar is again a wise choice.

But if an arrow won’t shoot right in a bow it is of no value no matter the savings. Fortunately, this is not the case with cedars. They do shoot. Today, there has been some misinformation of their construction and use, and many compound bow shooters, in an attempt to save on arrow costs, have tried cedar only to discard it as unfit for their type of bow. No. This does not work. It hardly works with aluminum when a broadhead is going to be used, let alone cedar. The cedar shaft should be selected right at the draw weight of the bow. If a compound is sixty pounds at twenty-eight inches, a sixty-pound arrow should be selected. If any doubt as to proper spine exists, then a cedar shaft over the draw wight of the bow should be chosen, not under. It will still be a very fast arrow. Because of the straight-up stance of the archer shooting a modern compound, draw length has increased over the past decade, and with longer arrows in use, it is even more important that the cedar be picked for good stiffness of spine. It won’t shoot well if it is too light for the compound bow.

Performance will be more than adequate. Out of a PSE Citation, sixty pounds at a twenty-eight-inch draw, a sixty-five-pound spined cedar shot at 213 feet per second on the chronograph. An aluminum 1816 beat it by only one fps, or 214. A Browning Nomad set at sixty pounds, twenty-nine inches, fired its cedar sixty spine arrows at 205, almost exactly what it got with aluminum. Out of a Cupid seventy-pound bow, thirty-one-inch draw, the seventy to seventy-five spine cedar reached 213, whipped only by a graphite shaft at 229. The big Jennings Arrowstar, seventy-pound, thirty-one inches, shot a seventy to seventy-five cedar at 243 feet per second. And the Schultz-made longbow surpassed 200 fps with cedars.

While cedar is not a replacement for the great aluminum shaft, it sure is a nice alternative, especially when a lot of field shooting is to be done. With a good jig, such as the Bitzenburger, absolutely excellent cedar arrows can be turned out swiftly. It’s easy. A shaft is cut to length first. A model-making saw such as the X-acto is perfect for this. A tool that resembles a pencil sharpener forms the nock end of the arrow. The nock is glued in place and then fletching, usually feather, but vanes will work well, too, is installed with the jig. On the business end of the arrow, it can be reduced in size with a tenon cutter and a switch-a-point may be added, or a cheap empty .38 Special cartridge case for plinking and small-game hunting. Naturally, for the longbow the arrow will probably be a fist-line choice, so a broadhead may be fitted on a taper, or the Bear switch-a-point may be installed so the same arrows can be used on the range and in the field. (More information on cedar shaft construction can be found in “How to Make an Inexpensive Small-Game Arrow,” BOW& ARROW’S Bowhunter’s Annual No.2.) The Coquille Indians didn’t have it so easy. They had to split the cedar stick with wedges first, then whittle it down with a shell knife and smooth it with sandstone, fitting stone or bone heads by hand. Their arrows were made the length of the shooter’s arm, and as big around as his little finger.

We’re luckier. Our cedar shafts come to us out of the box, normally in 11/32 size, but more and more in 23/64 for the really heavy bows. The white cedar we purchase is light in weight, strong and long lasting. A plant that produces thousands upon thousands of such shafts for the archer is the Rose City Archery Company of Powers, Oregon. The company began in Portland in 1939, and since Portland is known as the City of Roses, the firm called itself the Rose City Archery Company. In 1946, however, the factory moved to be closer to its wood source.

The Rose City company has received awards for environmental concern due to the nature of their business. First, unlike the Japanese, who cut green cedar, the Oregon arrow shaft makers never cut a living tree. Only deadfall and fire-kill wood is used. This allows the continuance of the living tree, which is good for the company as well as the general public. In an attempt to conserve energy, a successful measure has been taken by Rose City. They use all of their sawdust to both heat their plant during the winter months and dry the cedar as well, while supplying about a third of the world’s arrow shafts.

The operation is efficient. Run by three men, Ben Crabill, Noble Adamek, and Jim Adamek, the y produce from three to five million shafts per year. One person can grade up to 40,000 shafts in a single day at peak speed. They use only the superior wood for arrows, too. And since this practice would cause a terrific waste of cedar, Rose City has started a sideline they call their Monterrey Tub. This is a beautiful planter bucket coming in four sizes, and it uses up the cedar that is not suited for arrow shafts. Only straight grain, with no knots, becomes arrow material. The Adameks are natives of the Oregon country, and as youngsters often visited the archery company, never thinking that one day they would be running it. Noble took his college work in business administration, which has applied very well, and Jim has a masters in economics and his Ph.D. In engineering. The latter has been especially useful because all of the machines in the plant had to be designed from scratch and Jim understands their workings.

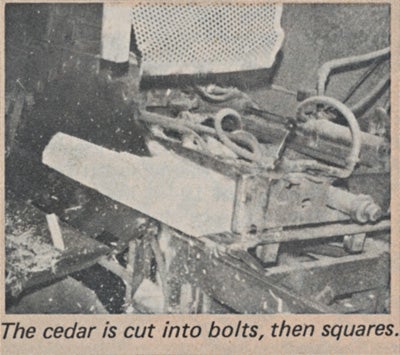

The process for getting a smooth, straight arrow shaft from a cedar tree has several stages. First, the felled log is trucked to the Rose City property and cut into bolts. The bolts are cut into squares. The squares are cut into boards and the boards are dried for up to several months. Then small square lengths of wood are cut from the boards to about arrow diameter, normally 11/32 or 23/64 and sometimes 5/16.

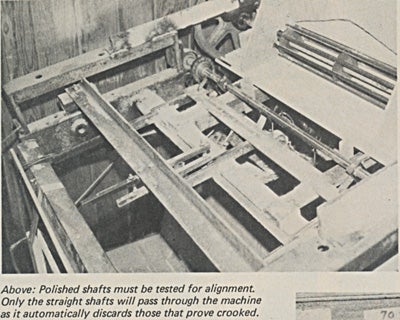

The square lengths of wood are then conveyed into one of seven dowel lathes, entering as four-sided, but emerging round, smooth and polished as well. The lathe cutters are only good for about one hour of this hard duty before they have to be re-honed to sharpness again. Only the straight shafts will be kept, and a machine does this operation, too, discarding shafts that are not true. These will not be thrown away either, but will be sold as plant supporters. Then the shafts are graded for spine, again by a machine. And finally, they are packaged up and mailed out to various companies, either to be resold to archers who will make their own arrows, or to be manufactured into painted arrows by a professional archery concern.

Cedar shafts will last a long time, some figure between two hundred and three hundred years, unless they hit a rock, of course. Storage usually is the place where good cedar arrows get warped. The arrows should be stored in a fairly dry place, even if they have been heavily painted. A rack made of two flat pieces of wood with holes for the arrows is a good way to keep the cedars straight. The two pieces of flat wood are separated by about twenty-two to twenty-six inches and held together by a couple of struts. It looks like a box kite in shape. The arrows are thrust through the holes on the top flat section, and then down through the corresponding holes on the bottom flat section. A middle section can be used if an archer wishes. The flat sections of wood can be about one-half-inch thick, and are all drilled at the same time so that the holes match up.

The Port Orford cedar arrow has been around for a long time, and it looks like it will be with us for some time to come. They are not replacement arrows for compounds, nor will they necessarily outdo the modern types of shafts. But they certainly have their place. In shooting the longbow, they are first-line equipment. In shooting the compound they can serve as first line, or as backup arrows on hunts, practice arrows, small game darts and varmint takers, all at a price that is very affordable and can give you some do-it-yourself fun in construction.

Leave a Reply

You must be logged in to post a comment.

Your Privacy Choices

Your Privacy Choices